Welding Instructions

XX WELDAHUBS® can be used with the following WELDASPROCKETS® sizes:

Minimum sizes: 4024X, 5020X, 6017X, 8014X, 10013X

WELDAHUBS® stock numbers are found on pages 31, 32 & 33

We recommend using Low Hydrogen Electrodes for welding WELDASPROCKET® parts.

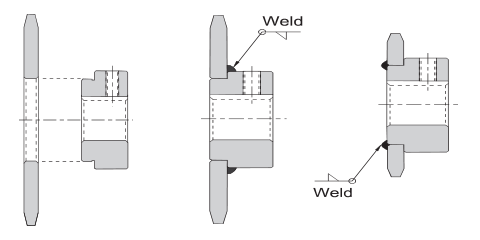

The larger WELDASPROCKET® should be welded as shown.

The smaller WELDASPROCKETS® should be welded as shown so the weld will not interfere with the chain.

Welding G&G Idler Hubs

The assembly of G&G Idler Hubs into a WELDASPROCKET® or WELDAPULLEY® is a relatively simple operation. As with WELDAHUBS®, the two parts are clamped together and stitch welded using low hydrogen electrodes, Three (3) or four (4) stitches 5/8’’ to 3/4’’ long will be sufficient. Care must be taken to make sure the welding ground circuit does not pass through the bearing itself. Excessive welding heat may cause distortion or damage to the bearing.